Hip implants transform many lives by restoring mobility and alleviating pain from hip-related conditions. Among the various advancements in orthopedic technology, our 3D acetabular cups, made with trabecular metal, stands out as a promising solution. This blog dives into the benefits of our innovative implants, the technology behind them, and how you can order one tailored to your needs.

Benefits of Trabecular Metal Technology

A cornerstone of the 3D ACT hip implant system is its incorporation of trabecular metal technology. This advanced material closely mimics the structure of natural bone, offering exceptional biocompatibility and promoting bone ingrowth.

The porous nature of trabecular metal provides a stable foundation for the implant, enhancing its longevity and reducing the risk of detachment. This process eliminates the need for coatings and additional fabrication processes used in traditional hip implants. Its design encourages natural load transfer by removing any interface between the porous structure and the bulk, which is vital for long-term osseointegration. Trabecular metal’s high coefficient of friction is also beneficial for reducing micromotions, promoting tissue growth while ensuring reliability and superior performance.

3D Printing Process

The precision and customization of our 3D ACT Hip Implants are made possible through cutting-edge 3D printing technology. This process allows for the creation of intricate, patient-specific designs that fit perfectly to each individual’s anatomy.

The manufacturing begins with reviewing CT scan slices submitted by healthcare providers planning 3D hip implant surgery for their patients. Based on the scan slices, a 3D conversion is done to develop a detailed model of the patient’s hip structure. Using Electron Beam Melting technology, titanium powder is melted to create a porous acetabular cup implant layer by layer, ensuring unparalleled accuracy. The result is a hip implant that not only meets but exceeds modern standards in orthopedic care.

Variations Available

At Madison Ortho, we offer two variations in the 3D ACT hip implant system:

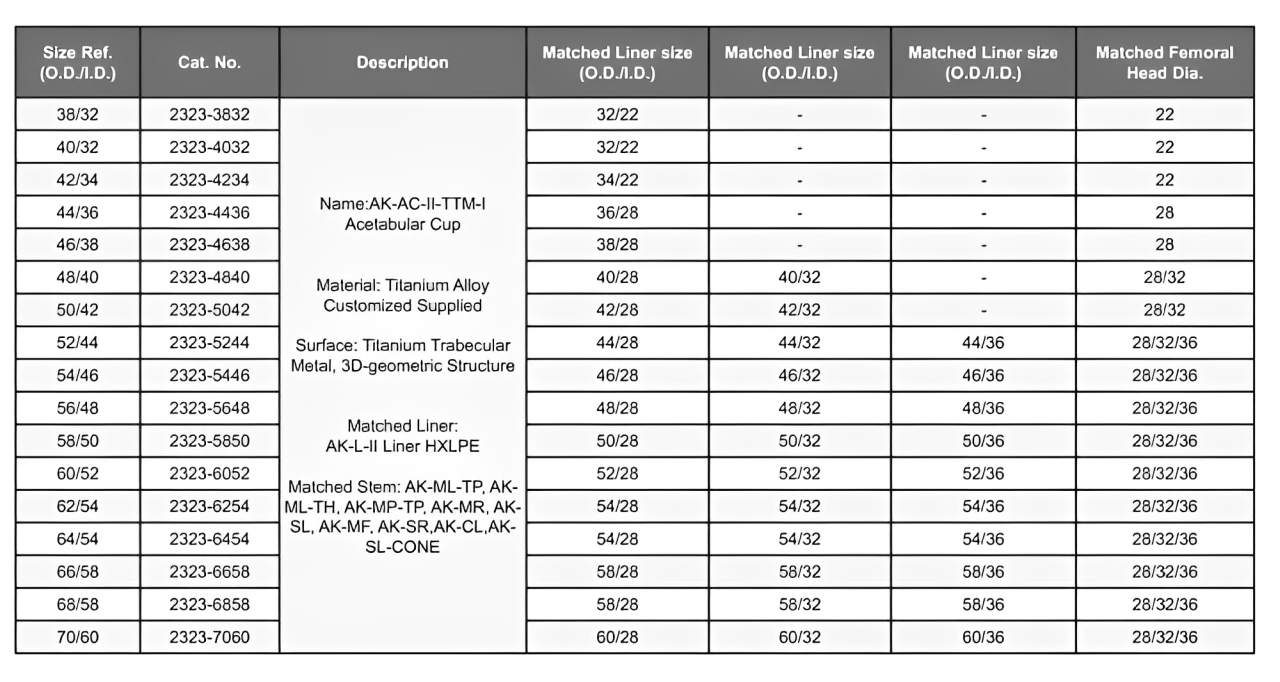

- AK-AC-II-TTM-I Acetabular Cup with outside/inside diameters ranging from 38/32 to 70/60

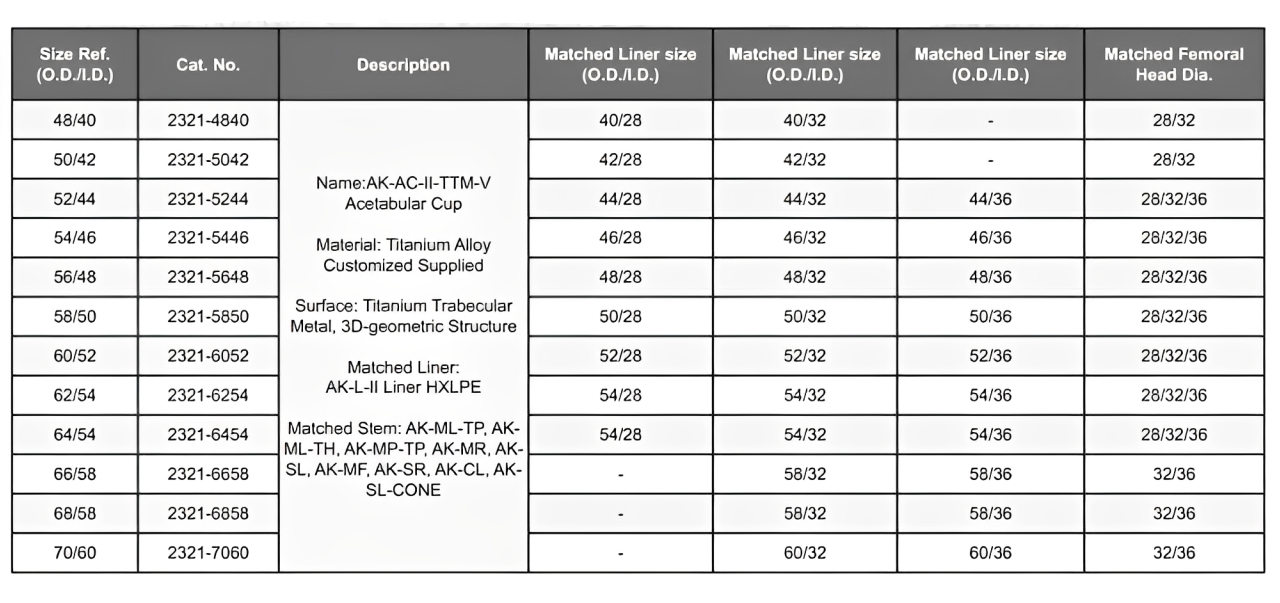

- AK-AC-II-TTM-V Acetabular Cup with outside/inside diameters ranging from 48/40 to 70/60

Both are available with matched liners and stems with different neck shaft angles, coatings, and several measurements.

We also offer the following as part of our 3D ACT system:

- 3D ACT Titanium Trabecular Augment

- TITAN artificial vertebral body, and

- METIS artificial cervical cage

How You Can Place an Order

Ordering our 3D ACT Hip Implants is a simple process. Healthcare providers can initiate the process by capturing the patient’s CT scan diagnostic images and measurements in a DICOM format (STL file), ensuring that the scan slice thickness is 0.6 mm. Files can be sent in CD format to our mailing address or as an email link via WeTransfer or Hightail. Our team of specialists will then design and produce the customized implant, ensuring timely delivery to your medical facility. For additional support, our dedicated customer service team is available to guide you through every step, from initial inquiry to post-surgery care.

Talk to the Experts

Madison Ortho is leading the way when it comes to customized orthopedic implants. Our 3D ACT Hip Implant system combines trabecular metal technology and 3D printing to deliver unparalleled quality and performance. With our patient-specific approach, advanced materials, and streamlined ordering process, this innovative solution is setting new standards for hip replacement surgery. To learn more about hip implants or discuss your requirements, call +1-787-945-5800 or email info@madisonorthoinc.com.